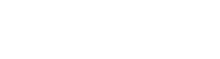

Spitfire Boat Trailers

How To Maintain Your Boat Trailer: Bearings, Brakes, and More

Owning a boat trailer is a significant investment, and like any investment, it requires regular maintenance to ensure longevity and reliability. At Spitfire Trailers, we understand the importance of keeping your trailer in top-notch condition, especially when transporting your prized boat. Here’s a detailed guide to help you maintain your boat trailer effectively.

Top 3 Boat Trailer Maintenance Tips

- Regular Cleaning: After every use, especially in saltwater, it’s crucial to wash your trailer with fresh water. Saltwater can be highly corrosive and can cause significant damage if not rinsed off.

- Inspection Routine: Regularly inspect your trailer for any signs of wear and tear. Look for rust, corrosion, or any loose parts and address them immediately.

- Lubrication:

Keep moving parts well-lubricated to prevent rust and ensure smooth operation. This includes the hitch mechanism and winch.

Let us talk about these maintenance tips in detail:

Regular Cleaning

After each use, especially if you’ve been in saltwater, it’s essential to rinse your trailer thoroughly with fresh water. This simple step can help wash away salt deposits and prevent the onset of corrosion.

Saltwater is notorious for its corrosive properties. When your boat trailer is exposed to saltwater, the salt can quickly begin to corrode metal parts, leading to rust and deterioration. This can significantly reduce the lifespan of your trailer and compromise its structural integrity.

Focus Areas:

- Axles and Bearings: These are particularly vulnerable to saltwater damage. Ensure they are thoroughly rinsed, as salt can cause bearings to seize and axles to corrode.

- Brakes and Wheels: Salt can affect the braking system, leading to reduced efficiency. Pay special attention to rinsing the brakes and wheels.

- Frame and Undercarriage: The frame of the trailer supports the entire structure and needs to be free from rust. Make sure the undercarriage is also rinsed, as salt can accumulate in hard-to-see areas.

Drying: After rinsing, allow your trailer to dry completely. This helps prevent moisture-related issues and further corrosion.

Regular Inspections: While cleaning, take the opportunity to inspect your trailer for any signs of rust or damage. Early detection can save you from costly repairs down the line.

Detailed Inspection Routine

Frequency: It’s recommended to perform a thorough inspection of your boat trailer at least once a month, or more frequently if you use your trailer often. This helps catch any potential issues early before they become serious problems.

Key Areas to Inspect:

- Frame and Structure:

- Rust and Corrosion: Check the entire frame for any signs of rust or corrosion. Pay special attention to welds and joints, as these areas are prone to developing rust.

- Structural Integrity: Look for any cracks or bends in the frame that could indicate stress or damage.

- Axles and Suspension:

- Wear and Tear: Inspect the axles and suspension components for any signs of wear, such as cracks or excessive play.

- Lubrication: Ensure that moving parts are well-lubricated to prevent friction and wear.

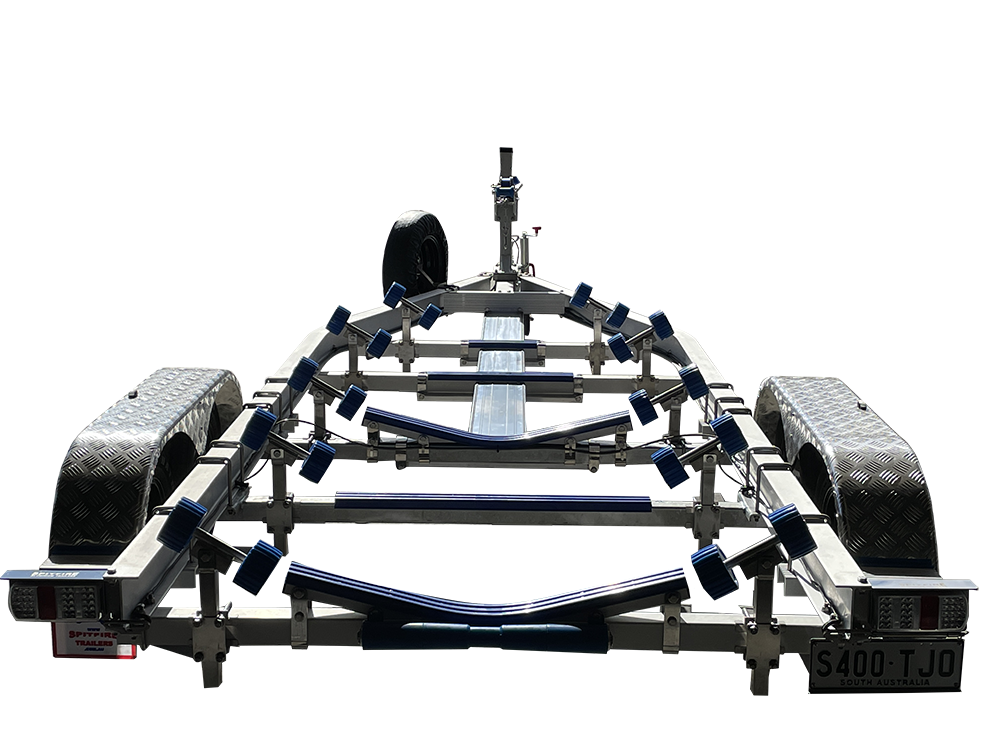

- Wheels and Tires:

- Tire Condition: Check the tires for any signs of wear, such as uneven tread or cracks. Ensure they are properly inflated to the recommended pressure.

- Wheel Nuts: Ensure that all wheel nuts are tight and secure.

- Brakes:

- Brake Pads and Discs: Inspect the brake pads for wear and ensure the discs are free from rust and corrosion.

- Brake Fluid: Check the brake fluid level and top up if necessary.

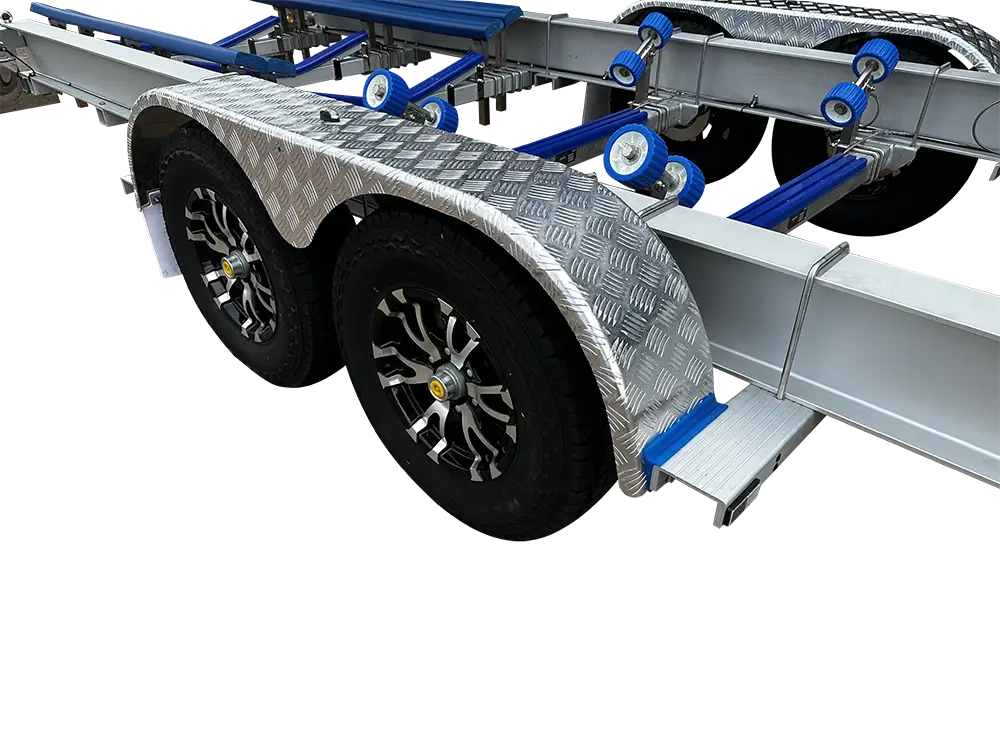

- Lights and Wiring:

- Functionality: Test all lights, including brake lights, indicators, and side markers, to ensure they are working correctly.

- Wiring Condition: Inspect the wiring for any signs of fraying or damage.

- Hitch and Coupling:

- Security: Ensure the hitch is secure and free from rust. Check the coupling mechanism for smooth operation.

- Safety Chains and Straps:

- Condition: Check for any signs of wear or damage. Ensure they are of the correct length and securely attached.

Immediate Action: If you notice any issues during your inspection, address them immediately. Delaying repairs can lead to more significant problems and potentially unsafe conditions.

By incorporating these inspections into your routine, you can maintain your trailer’s reliability and safety, ensuring peace of mind while transporting your boat.

Lubrication

Lubrication is crucial for maintaining the smooth operation of your trailer’s moving parts. It helps reduce friction, prevents rust, and extends the lifespan of components by minimizing wear and tear.

Key Components to Lubricate:

- Hitch Mechanism:

- Functionality: The hitch is vital for connecting your trailer to your vehicle. Keeping it well-lubricated ensures smooth coupling and uncoupling.

- Lubrication Points: Apply grease to the ball mount and coupler latch. This prevents rust and ensures easy movement.

- Winch:

- Smooth Operation: The winch is used to load and unload your boat. Proper lubrication ensures it operates smoothly and reduces strain on the mechanism.

- Lubrication Points: Grease the winch gears and handle pivot points. This helps in smooth cranking and prevents corrosion.

- Axles and Bearings:

- Friction Reduction: Regularly grease the wheel bearings to reduce friction and prevent overheating. This is crucial for safe towing.

- Maintenance Schedule: As mentioned earlier, grease the bearings every 6 months or every 1,000 miles.

- Suspension Components:

- Longevity: Lubricating the suspension components, such as leaf springs and shackles, helps in maintaining their flexibility and prevents rust.

- Other Moving Parts:

- General Maintenance: Any other moving parts, such as the jack stand or folding steps, should also be lubricated to ensure they function smoothly.

Choosing the Right Lubricant

Use a high-quality marine-grade grease that is resistant to water washout, especially if your trailer is exposed to saltwater environments. This type of grease provides better protection against corrosion and wear.

Application Tips:

- Clean Before Lubricating – Ensure all parts are clean and free from old grease or debris before applying new lubricant. This ensures maximum effectiveness.

- Regular Schedule – Incorporate lubrication into your regular maintenance schedule to keep everything in optimal condition.

Consistent lubrication is a simple yet effective way to enhance the performance and longevity of your trailer.

Boat Trailer Wheel Bearings Maintenance

When to Grease

Grease your boat trailer bearings every 6 months or every 1,000 miles, whichever comes first. This helps in preventing friction and overheating.

When to Replace

Check for any unusual noises or vibrations while towing. If you notice any, it might be time to replace the bearings. Typically, bearings should be replaced every 3-5 years, depending on usage.

Maintenance for Brakes

Brakes are a critical component of your trailer. Regularly check the brake pads for wear and replace them if they are thin. Ensure brake fluids are topped up and the system is free of leaks.

Wiring and Lighting

Check the wiring for any frays or corrosion. Ensure all lights are functioning correctly, including brake lights and indicators, for safe towing.

How Spitfire Boat Trailers Can Help with Boat Trailer Maintenance

At Spitfire Trailers, we understand that maintaining your boat trailer is essential for ensuring safety and longevity. That’s why we offer comprehensive boat trailer services and maintenance to keep your trailer in top condition. Our expert team is equipped to handle everything from routine inspections to complex repairs, ensuring your trailer is always ready for the road. For more details on our services, visit our service page.

In addition to maintenance services, Spitfire Trailers also offers a wide range of high-quality boat trailers designed to meet various needs and specifications. Whether you’re looking for a new trailer or need advice on the best options for your boat, our selection ensures you find the right fit. Explore our full range of trailers on our shop page. With Spitfire Trailers, you can trust that both your trailer’s maintenance and purchasing needs are in expert hands.

A Maintenance Checklist you can use at home

Inspect for Rust and Loose Parts | Regularly check the trailer for any signs of rust, especially on the frame and joints. Tighten any loose parts to ensure safety and stability. |

Grease Bearings Every 6 Months | Apply marine-grade grease to the wheel bearings every 6 months to reduce friction and prevent overheating, ensuring smooth and safe towing. |

Check Brake Pads and Fluid Levels | Inspect the brake pads for wear and ensure the brake fluid is at the correct level to maintain effective braking performance. |

Inspect Wiring and Lights | Test all lights, including brake and indicator lights, to ensure they are functioning correctly. Check wiring for any damage or corrosion. |

Lubricate Moving Parts | Apply lubricant to the hitch mechanism, winch, and other moving parts to prevent rust and ensure smooth operation. |

Contact Us

For more information on maintaining your boat trailer or to schedule a service, contact us or call us now at (07) 4440 0010.

Maintaining your boat trailer is essential for safety and performance. By following these tips, you can ensure your trailer remains in excellent condition for many adventures to come. Happy boating!